BLOG

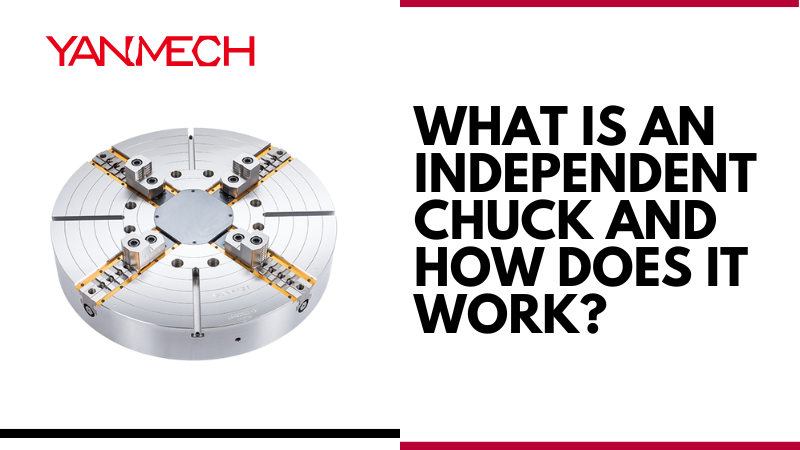

What Is an Independent Chuck and How Does It Work?

When it comes to holding irregular or heavy workpieces on a lathe, few tools offer the flexibility and strength of the independent chuck. Used widely in heavy-duty machining, maintenance workshops, and custom part manufacturing, independent chucks are prized for their adaptability and solid clamping force. But what exactly is an independent chuck, and how does it work?

With decades of experience in developing precision workholding solutions, YANMECH Industrial Co., Ltd. has seen firsthand how independent chucks contribute to machining flexibility and efficiency. In this article, we explain how these chucks work, where they’re used, and why they remain an essential tool in modern manufacturing environments.

What Is an Independent Chuck?

An independent chuck is a type of lathe chuck where each jaw is controlled by its own screw mechanism and can move independently from the others. This differs from a scroll chuck (also known as a self-centering chuck), where all jaws move together in a synchronized motion.

Independent chucks are most commonly found in:

- 4-jaw configurations (also called 4-jaw independent chucks)

- Manual lathes, vertical lathes, and CNC turning centers

- Heavy-duty and high-torque machining operations

How Does an Independent Chuck Work?

Each jaw of an independent chuck is adjusted manually using a wrench. The operator rotates the screw on each jaw individually to clamp onto the workpiece. Because each jaw can be positioned independently, this chuck allows for:

- Clamping irregular, non-cylindrical shapes (e.g., squares, rectangles, castings)

- Precisely centering a workpiece by manually adjusting each jaw with a dial indicator

- Handling larger or heavier parts that require specific clamping positions

Although it takes more time to set up than a self-centering chuck, the independent chuck offers maximum versatility for non-standard jobs.

Key Features of Independent Chucks

- Independent jaw movement for clamping asymmetrical or off-center parts

- High clamping force, ideal for heavy and rigid machining tasks

- Durable construction, often made from hardened steel or cast iron for longevity

- Manual control allows for custom positioning and adjustments

- Reversible jaws in many models, for internal or external clamping needs

Benefits of Using an Independent Chuck

- Flexibility – Clamp virtually any shape, from round bars to irregular castings

- Accuracy – Fine-tune jaw positions with indicators for perfect centering

- Strength – Withstand the force of large cuts and heavy components

- Cost-Effective – One chuck can accommodate a wide range of part geometries

- Essential for Custom Jobs – Especially in repair work and low-volume production

Independent Chuck vs. Scroll Chuck: A Quick Comparison

| Feature | Independent Chuck | Scroll Chuck (Self-Centering) |

|---|---|---|

| Jaw Movement | Individual, manually adjusted | Simultaneous, gear-driven |

| Setup Time | Longer | Faster |

| Workpiece Shape | Any shape (round, square, etc.) | Mostly round or symmetrical shapes |

| Clamping Precision | Manually controlled, very precise | Centered automatically |

| Best for | Custom parts, heavy workpieces | Mass production, quick jobs |

Applications of Independent Chucks

Independent chucks are widely used in industries such as:

- Heavy machinery – Large flanges, gears, and castings

- Repair and maintenance – Reworking used parts or one-off components

- Oil and gas – Machining large valves or fittings

- Shipbuilding – Turning oversized cylindrical or non-round parts

- Steel and foundry – Clamping raw materials with uneven surfaces

Whether in a CNC or manual environment, the independent chuck gives machinists full control over clamping—something essential when precision and flexibility are key.

YANMECH Independent Chucks: Built for Strength and Flexibility

For operations that require strong, adaptable clamping, YANMECH Industrial Co., Ltd. offers high-quality independent chucks designed for precision and durability. Each model features:

- Forged steel construction for maximum strength

- Individually adjustable jaws for clamping irregular shapes

- Optional adapter plates for different machine spindles

- Chip-sealed design for better protection in tough environments

- Custom specs available upon request

These chucks are ideal for lathes, milling, and grinding machines—especially when handling heavy, eccentric, or asymmetrical workpieces.

☛ Explore YANMECH Independent Chucks ›

Conclusion

The independent chuck is a versatile and powerful tool in any machinist’s arsenal. While it may require more time to set up than a self-centering chuck, its ability to handle irregular shapes, large parts, and high-precision clamping makes it indispensable in many manufacturing scenarios.

If your workshop demands flexibility, strength, and control, it’s time to consider upgrading to a high-quality independent chuck—one that’s built to meet the needs of your toughest machining tasks.

Looking for the right solution? Contact YANMECH Industrial Co., Ltd. today to learn more about our independent chucks or request a quote tailored to your application needs. Our team is ready to assist you with expert advice and dependable product support.