PRODUCTS

BOX JAWS

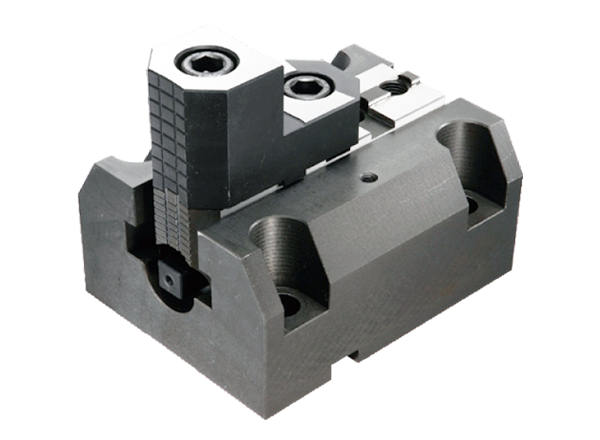

Mseries (2 Piece Jaw) BOX JAWS

The 2-piece jaws can be replaced with hard jaws and soft jaws.

Made of high-quality alloy steel, they offer excellent wear resistance and deformation resistance.

Undergoing strict heat treatment and grinding processes, they enhance surface hardness and durability.

LEARN MORE Made of high-quality alloy steel, they offer excellent wear resistance and deformation resistance.

Undergoing strict heat treatment and grinding processes, they enhance surface hardness and durability.

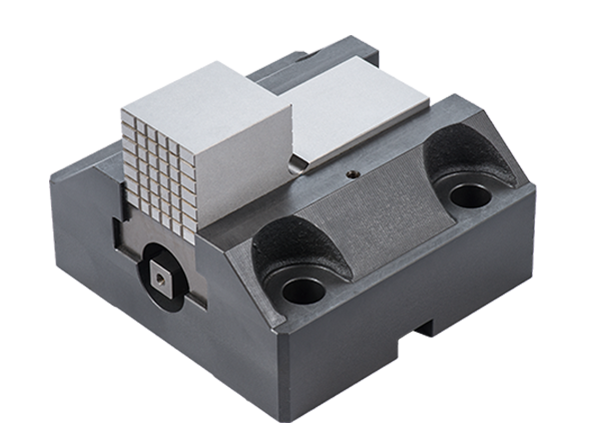

Mseries BOX JAWS

Made of high-quality alloy steel, they offer excellent wear resistance and deformation resistance.

Undergoing strict heat treatment and grinding processes, they enhance surface hardness and durability.

LEARN MORE Undergoing strict heat treatment and grinding processes, they enhance surface hardness and durability.

A Chuck Jaw is a replaceable clamping component used to hold workpieces in place during machining. It is typically mounted on a faceplate or chuck using T-slot bolts, and is suitable for various machine sizes and table configurations. Chuck jaws are widely applied in large vertical lathes, gantry milling machines, CNC machine tools, and grinders.

Depending on the machining requirements, users can choose between hard jaws and soft jaws. Soft jaws can be re-machined to match the contour of the workpiece, ensuring higher clamping accuracy and surface protection.

Chuck jaws are designed with attention to clamping force distribution, wear resistance, and ease of installation. Selecting the right jaws enhances workpiece stability, machining efficiency, and surface quality—making them an essential component of any workholding system.

Depending on the machining requirements, users can choose between hard jaws and soft jaws. Soft jaws can be re-machined to match the contour of the workpiece, ensuring higher clamping accuracy and surface protection.

Chuck jaws are designed with attention to clamping force distribution, wear resistance, and ease of installation. Selecting the right jaws enhances workpiece stability, machining efficiency, and surface quality—making them an essential component of any workholding system.