PRODUCTS

SELF CENTERING SCROLL CHUCKS

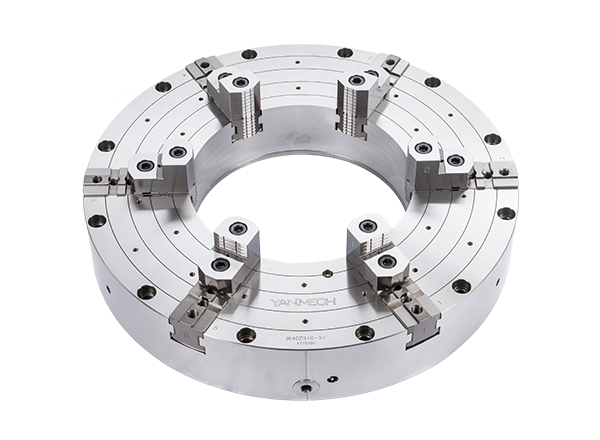

Iseries (Self centering scroll chucks) SELF CENTERING SCROLL CHUCKS

The Self centering scroll chucks is a versatile and efficient clamping solution designed with a through-hole, making it ideal for long workpieces or integration with special fixtures. With simple manual operation, all jaws move simultaneously to ensure secure, stable clamping and fast setup. Its robust construction and ease of use make it well-suited for lathe operations, pipe machining, and applications requiring center-through access.

Key Features:

Hollow Design: The central through-hole accommodates long shafts or tubular workpieces, ideal for complex clamping needs.

Synchronized Clamping: All jaws move in unison, providing even clamping force and minimizing workpiece deformation.

Easy Manual Operation: No pneumatic or hydraulic systems required—simple to install, operate, and maintain.

High-Strength Construction with Heat Treatment: The chuck body, master jaws, and screws are made from high-strength alloy steel and fully heat-treated for superior rigidity, wear resistance, and extended service life.

Flexible Applications: Widely used in lathes, automation systems, and fixture setups—especially suitable for small to medium production runs with varied workpiece types.

LEARN MORE Key Features:

Hollow Design: The central through-hole accommodates long shafts or tubular workpieces, ideal for complex clamping needs.

Synchronized Clamping: All jaws move in unison, providing even clamping force and minimizing workpiece deformation.

Easy Manual Operation: No pneumatic or hydraulic systems required—simple to install, operate, and maintain.

High-Strength Construction with Heat Treatment: The chuck body, master jaws, and screws are made from high-strength alloy steel and fully heat-treated for superior rigidity, wear resistance, and extended service life.

Flexible Applications: Widely used in lathes, automation systems, and fixture setups—especially suitable for small to medium production runs with varied workpiece types.

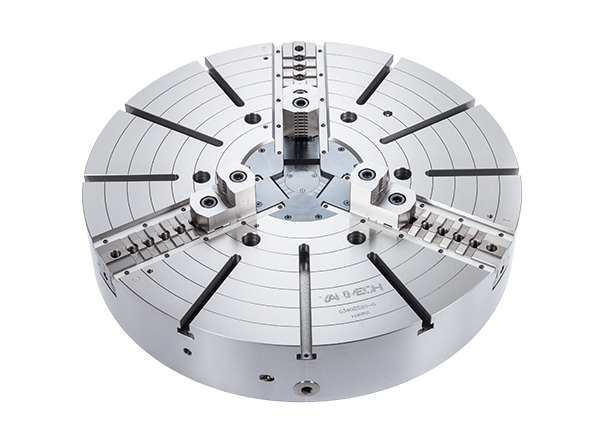

Gseries (Closed center self centering scroll chucks) SELF CENTERING SCROLL CHUCKS

• Cast iron or forged steel body.

• Install side strips and chips cover sealed base jaw to prevent chips and coolant ingress.

• High accuracy of repeated positioning.

• Special specifications can be customized.

LEARN MORE • Install side strips and chips cover sealed base jaw to prevent chips and coolant ingress.

• High accuracy of repeated positioning.

• Special specifications can be customized.

The self centering scroll chuck is a reliable and widely used clamping device designed for quick and secure workpiece holding. Through simple manual operation, all jaws move simultaneously to open or close, ensuring fast setup and consistent clamping force.

Features:

• Synchronized Clamping:All jaws move in unison toward the center or outward, delivering even clamping pressure and preventing workpiece deformation.

• Quick Operation:Compared to single-jaw systems, the self-centering mechanism allows faster loading and unloading, significantly improving work efficiency.

• Wide Applicability:Its simple and robust design makes it ideal for applications where frequent workpiece changes are required.

• Durable Construction:Made from high-strength materials, the chuck offers excellent durability and stable clamping performance.

• Cost-Effective Solution

Without the need for pneumatic or hydraulic power, this manual chuck is an economical and practical choice for a variety of machining setups.

Features:

• Synchronized Clamping:All jaws move in unison toward the center or outward, delivering even clamping pressure and preventing workpiece deformation.

• Quick Operation:Compared to single-jaw systems, the self-centering mechanism allows faster loading and unloading, significantly improving work efficiency.

• Wide Applicability:Its simple and robust design makes it ideal for applications where frequent workpiece changes are required.

• Durable Construction:Made from high-strength materials, the chuck offers excellent durability and stable clamping performance.

• Cost-Effective Solution

Without the need for pneumatic or hydraulic power, this manual chuck is an economical and practical choice for a variety of machining setups.